Modularization is Key

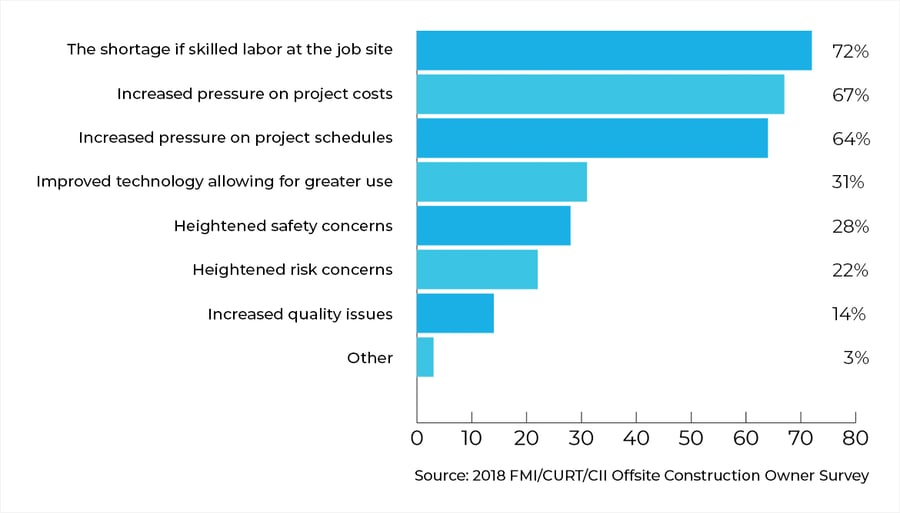

How can the current U.S. industry be transformed to include, and therefore benefit from, all the pro’s offsite construction provides? The three elements that need to be considered as the main pillars of strategy for every prefab project are project delivery, people, and planning. Al Schwarzkopf, associate director with Merck and Co., Inc., stated, “In order for us to have a radical change in productivity as an industry, we’ve got to revolutionize the way we deliver projects.

Modularization is probably one of the key components in being able to take that first step.

The pillar elements for a successful strategy of adopting offsite construction are NOT being executed across teams and projects...yet. “There’s outdated procurement practice and decision-making models that hinder many owner organizations from breaking out of antiquated processes and related behaviors.”

Strategic Planning

The best way to start adopting offsite construction methods is for owner organizations to have “an early and deliberate decision.” Start learning about industry best practices, the first being strategic planning. Ask why you’re pursuing offsite construction. Successful companies in the industry who’ve adopted offsite construction have “selected an executive-level champion to lead the offsite construction initiative and align all teams with company’s overall project execution vision and strategy.”

Points to Consider in the Planning Phase

With offsite construction, project planning must include (but is not limited to):

- Firms available to the owner with expertise in prefabrication that can be considered for the project

- Offsite resources (e.g., real estate) for fabrication and staging

- Logistics/shipping and delivery of large prefabricated assemblies to the job site

- Specific skills and equipment associated with offsite construction activities

Design and Delivery Approach

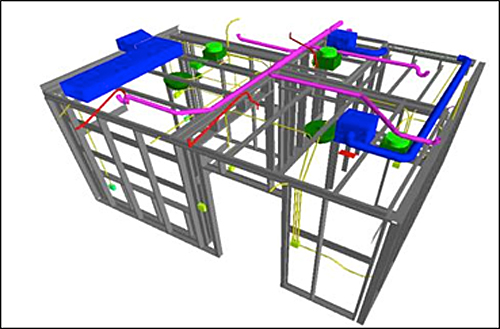

After planning has been thoroughly thought through and communicated, the design phase “must drive the coordination and production of architectural and engineering drawings.” With the offsite construction delivery approach, “the construction drawings could conceivably be exclusively produced by the contractor and specialty trades with further coordination and code compliance review by the architecture or engineering firm(s).”

What does this ‘upfront planning’ actually look like when played out practically? Peter Dumont, Vice President of Global Strategic Projects at Pentair Thermal management sums it up well in Rethinking Offsite Construction:

Offsite work requires a lot of up-front planning, which needs to be completely analyzed and prepared for during FEED. It also requires much special design and material selection considerations. You just can't take stick-built designs and cut them up into modules. You have to perform modular-based design upfront and plan the myriad of material, logistical and scope-split types of issues into the process.