- 1.800.966.8883

- sales@wilmotmodular.com

- 5812 Allender Rd. White Marsh, MD 21162

Products We Offer

Immediate Availability! 8'x20' and 8'x40' Container Offices

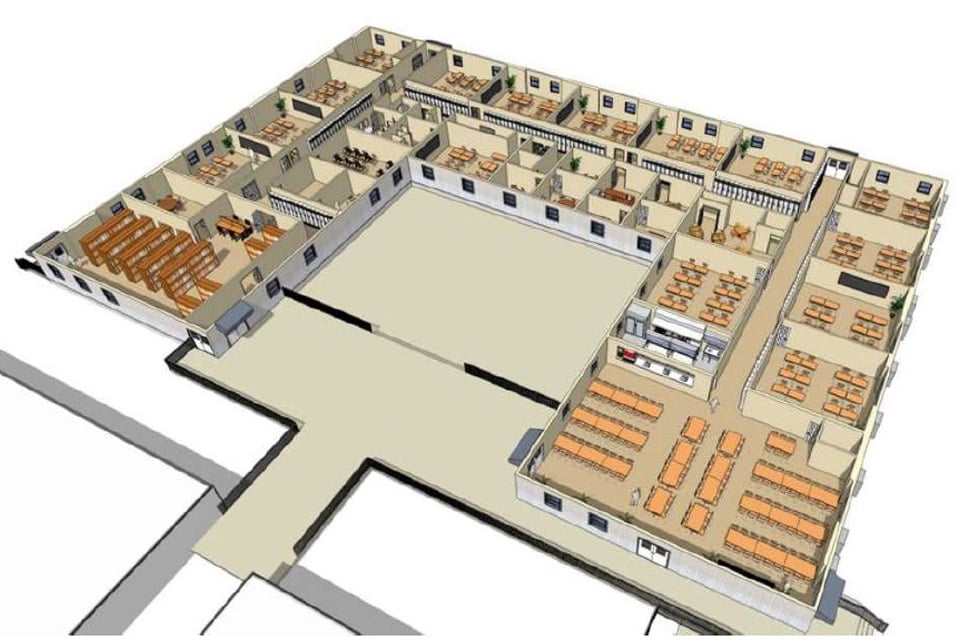

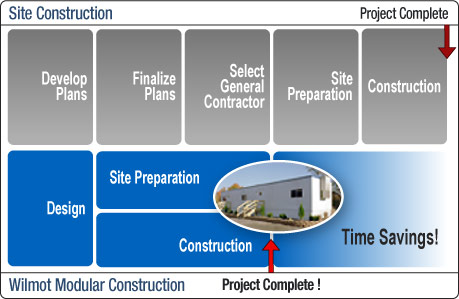

Modular Building Services

Immediate Availability! 8'x20' and 8'x40' Container Offices

Industries We Serve

Immediate Availability! 8'x20' and 8'x40' Container Offices!

About Wilmot Modular Solutions

Immediate Availability! 8'x20' and 8'x40' Container Offices